How to install Ford IDS 109:

1- Install the ids 86 before changing the date to 1 07 2015

1- Install the ids 86 before changing the date to 1 07 2015

(hold the date 1/7/2015 , until you finish step 5

every time you restart your computer, check the date, if it is on 1/7/2015)

2- install patch ( choice option 2 )

3- Make a backup of your windows system (I recommend, this is optional)

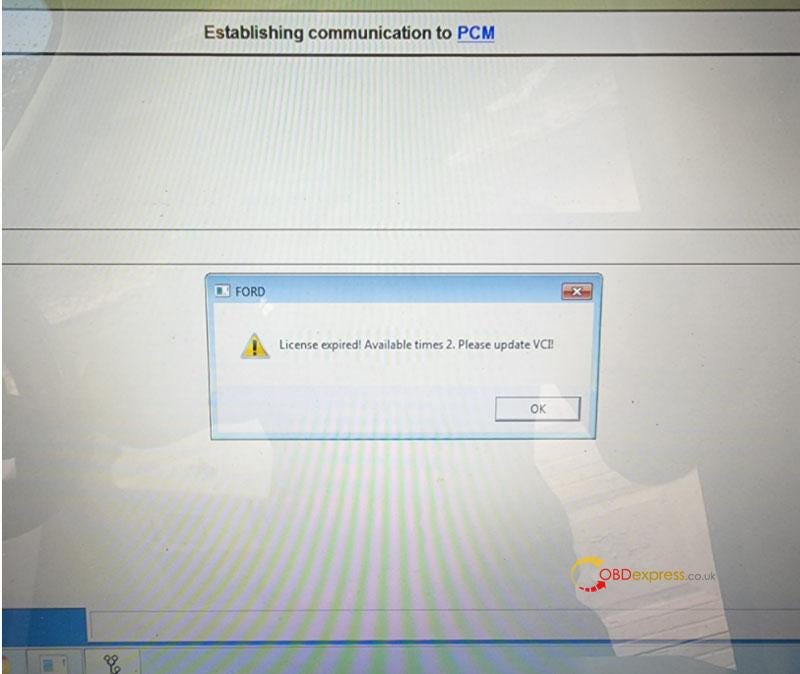

4- Open the program with the interface connected ,,( choose NON DEALER,when open program for first time ) , keep vcm turn on,on the computer.

5 – create a restore point,,,then turn off vcm of the computer

6 – Okay, now install the new version, v109.01, before installing, changing the date of your computer, to the current day

7- After installing, go back to the restore point, which you created in step 5, activate this restore point, and then open the program

8- Finally, install FordExtendProgram (click right mouse button click on, run as administrator)

Done, will work in the new version

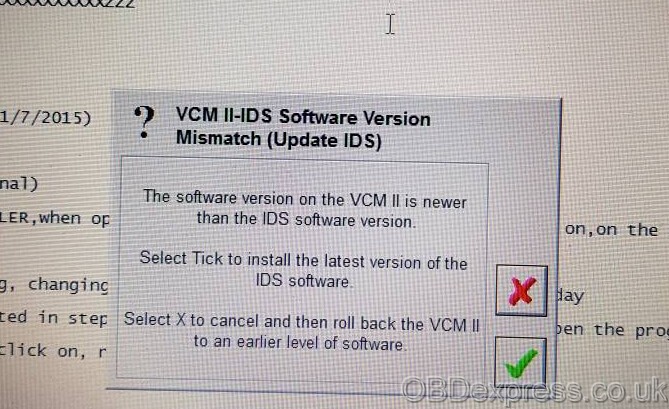

Ps. here’s solution of “VCM II-IDS software version mismatch (update IDS) ”

Click green Tick box to update firmware.

If it does nothing, <=Perform VCMii reset . Unplug USB cable from end VCM take off black rubber end boot plug back in USB restart IDS hold BUTTON middle end VCM plug in to PC all lights flash and and when VCM beeps release button IDS will prompt VCM update to IDS level press Tick

Note that Ford IDS V109 can be download for free from http://blog.obdexpress.co.uk/2018/04/11/mazda-ids-109-download-free-on-mega/ But it’s not tested by professionals. If you want to have IDS with security and relief, you’re advised to spend some dollars with it: http://www.obdexpress.co.uk/wholesale/ford-vcm-ids-v108.01-software.htmltested 100%, confirmed to work perfect with VCM 2 clone